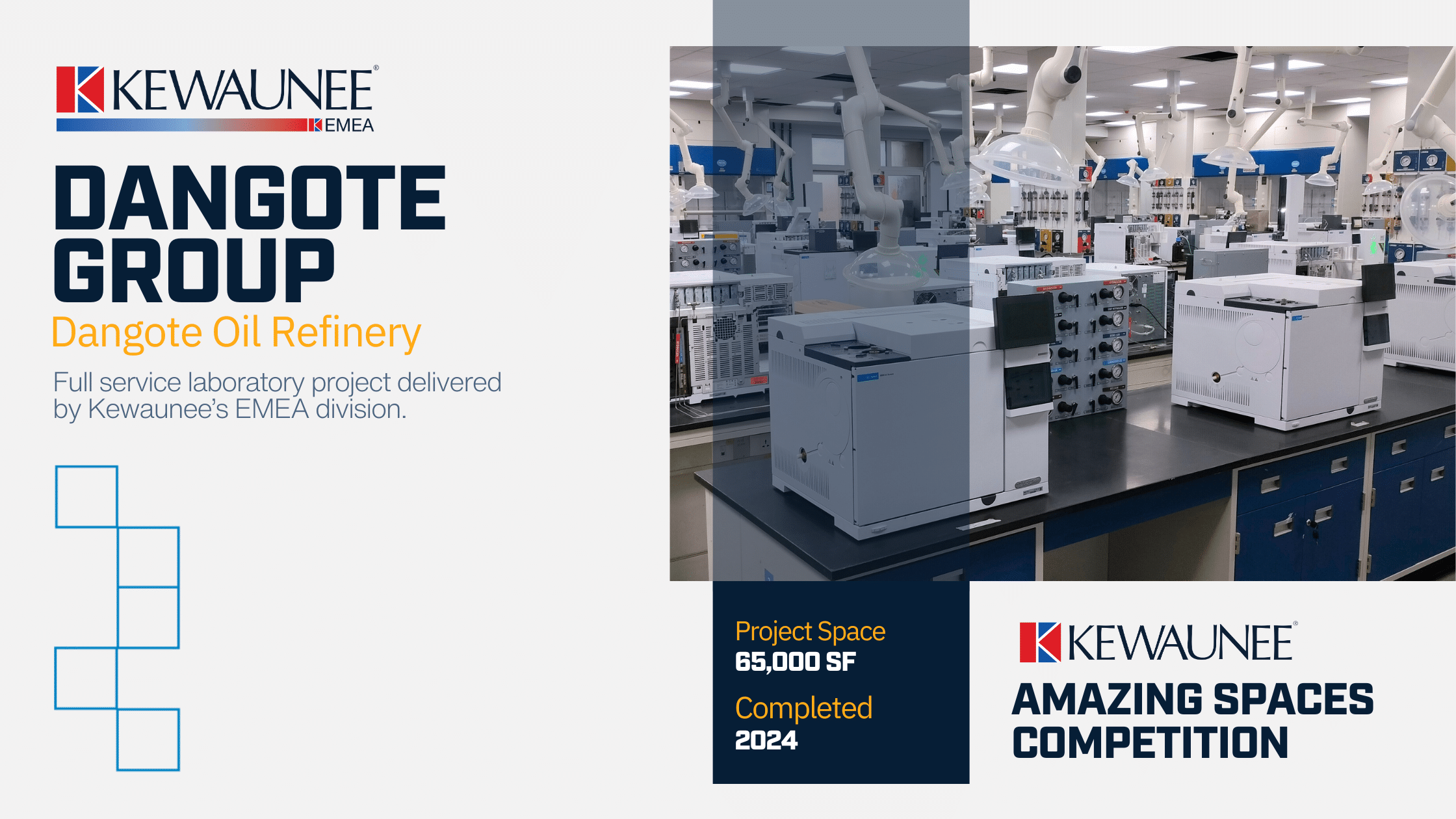

Welcome back to Kewaunee’s Amazing Spaces competition blog series! We’re excited to take you on a journey through some of the most innovative and inspiring scientific spaces around the world. Today, we’re shining a spotlight on the Dangote Oil Refinery, a state-of-the-art laboratory space delivered by Kewaunee’s EMEA division.

Project Overview

This amazing space supports the Dangote Oil Refinery, a 650,000 barrels per day (BPD) integrated refinery in the Lekki Free Zone near Lagos, Nigeria. As Africa’s largest oil refinery and the world’s largest single-train facility, it is capable of meeting 100% of Nigeria’s refined product requirements, with a surplus for export.

The refinery features the world’s largest pipeline infrastructure, with approximately 1,100 kilometers handling three billion standard cubic feet of gas per day. This multi-billion-dollar project creates a market for approximately $21 billion per annum of Nigerian crude. The refinery processes both Nigerian and other crudes.

Project Goals

The primary goals for this project included:

- Supporting Petroleum Quality Control: Providing comprehensive lab instrumentation and commissioning for petroleum quality control.

- Ensuring Safety and Efficiency: Installing advanced exhaust systems and designing a reliable gas distribution infrastructure.

- Delivering Cutting-Edge Solutions: Providing and commissioning state-of-the-art lab equipment to support the refinery’s operations.

Kewaunee Products Utilized

The project utilized 67 fume hoods, 800 running meters of lab furniture, 840 cabinets, and 850 square meters of worktops.

Special Considerations

Kewaunee’s EMEA division was responsible for the facility’s entire petroleum quality control lab instrumentation and commissioning, as well as the laboratory infrastructure. The team delivered state-of-the-art lab solutions through multiple phases of the project. This included installing advanced exhaust systems to ensure a safe and controlled environment, designing a reliable gas distribution infrastructure, and providing and commissioning cutting-edge lab equipment.

Turnkey support for this amazing space included:

- Comprehensive Design-Build Services: Lab planning, furnishing, HVAC systems, gas distribution, and commissioning.

- Global Standards Compliance: Adherence to international lab safety and design standards.

- Large-Scale Project Execution: Expertise in lab infrastructure solutions, promoting innovation and best practices.

- Lab Equipment Placement & Integration: Advanced equipment installation for fully operational labs.

- Sustainable Lab Design: Focus on energy-efficient systems and eco-friendly solutions.

- In-House Manufacturing Capabilities: Precision manufacturing of lab furniture and equipment.

- End-to-End Lifecycle Support: From design and installation to training and maintenance.

Project Gallery

We hope you were inspired by this glimpse into the Dangote Oil Refinery’s laboratory space. Keep following our Amazing Spaces competition series as we journey through and celebrate the most innovative and transformative spaces in the world of science and research.

USA

USA  India

India